|

Anping Zhongrun Metal Mesh Products Co., Ltd.

|

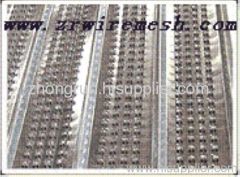

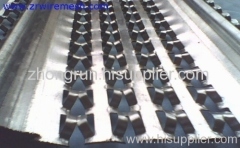

GI Concret Formwork

| Price: | 3.1~3.9 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

it has better anti-stress capability and forming flexibility than normal metal lath

Concret Formwork, consisting of steel sheets formed into mesh and U pattern rib bone, will produce a surface with concrete which will bond directly to the next pour without any special treatment. High-ribbed formwork is widely used in building construction to form retaining walls, columns, stop ends, construction joints and used to support slab flooring.

Features:

1. Visual Concrete Pouring

Because it is comprised of porous open mesh, high-ribbed formwork reduces the risk of voids and/or honeycombing occurring within the concrete.

2. Lightweight and Convenience for Transportation and Installation

High-ribbed formwork is only 10% as heavy as the common steel module, featuring fast installation and convenient transportation.

3. Suitable for Segmented Concrete

High-ribbed formwork is a permanent one that is easy for concrete to bond with the next pour without dismantling the formwork or making a juncture, thus simplifying bonding work.

4. Good Mechanical Performance and Low Side Pressure

High-ribbed formwork is only subject to 60% of side pressure compared with common formwork, thus enabling to decrease weight of rib bone by 40%.

5. Easy for Muff Coupling, Shearing, Optimizing Technologies and Increasing Shearing Strength

High-ribbed formwork will produce an ideal surface with high shearing strength combined with poured mortar that will penetrate into the formwork through the mesh pores.

6. High-ribbed formwork is multifunctional, easy to cut and bendable to form different shapes to meet different requirements.

1. Visual Concrete Pouring

Because it is comprised of porous open mesh, high-ribbed formwork reduces the risk of voids and/or honeycombing occurring within the concrete.

2. Lightweight and Convenience for Transportation and Installation

High-ribbed formwork is only 10% as heavy as the common steel module, featuring fast installation and convenient transportation.

3. Suitable for Segmented Concrete

High-ribbed formwork is a permanent one that is easy for concrete to bond with the next pour without dismantling the formwork or making a juncture, thus simplifying bonding work.

4. Good Mechanical Performance and Low Side Pressure

High-ribbed formwork is only subject to 60% of side pressure compared with common formwork, thus enabling to decrease weight of rib bone by 40%.

5. Easy for Muff Coupling, Shearing, Optimizing Technologies and Increasing Shearing Strength

High-ribbed formwork will produce an ideal surface with high shearing strength combined with poured mortar that will penetrate into the formwork through the mesh pores.

6. High-ribbed formwork is multifunctional, easy to cut and bendable to form different shapes to meet different requirements.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!